Home / Swing Motors

Swing Motors

EXCAVATOR SWING MOTORS

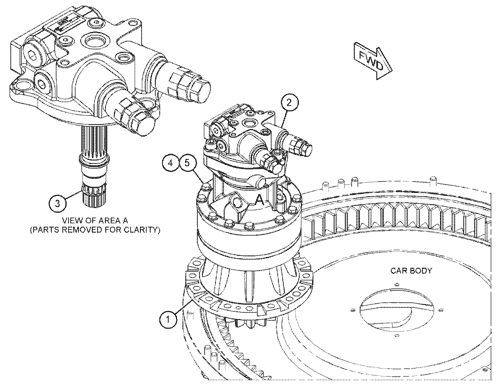

The excavator swing mechanism is a unique working system of the excavator to ensure 360-degree rotation of the cockpit.

The excavator swing mechanism includes a swing motor, a swing drive and a swing control

The swing time of the swing mechanism accounts for about 50-70% of the entire working cycle time, the energy consumption accounts for about 25-40%, and the heat generated by the swing hydraulic oil circuit accounts for about 30-40% of the total heat generated by the hydraulic system. The basic requirement for the swing mechanism is to shorten the cycle time as much as possible on the premise that the combat torque and acceleration do not exceed the allowable values.

The Function of Swing Motor

The swing motor is a key component of the swing mechanism. It can convert the oil pressure provided by the main pump into mechanical energy and input it to the reduction box. The quality of its working performance will directly affect the rotation speed, driving torque, rotation parking and parking brake of the whole machine, and is the key to determining the productivity of the whole machine.

Swing motors are divided into two categories: low-speed high-torque motors and high-speed swing motors.

Low-speed and high-torque motors are rarely used in the swing mechanisms of modern excavators due to their large size and heavy weight. High-speed swing motors are small in size and light in weight, which facilitates the rational layout of the swing mechanism and can also meet different rotation speeds and Torque requirements, so it is widely used.

The Structure of Swing Motor

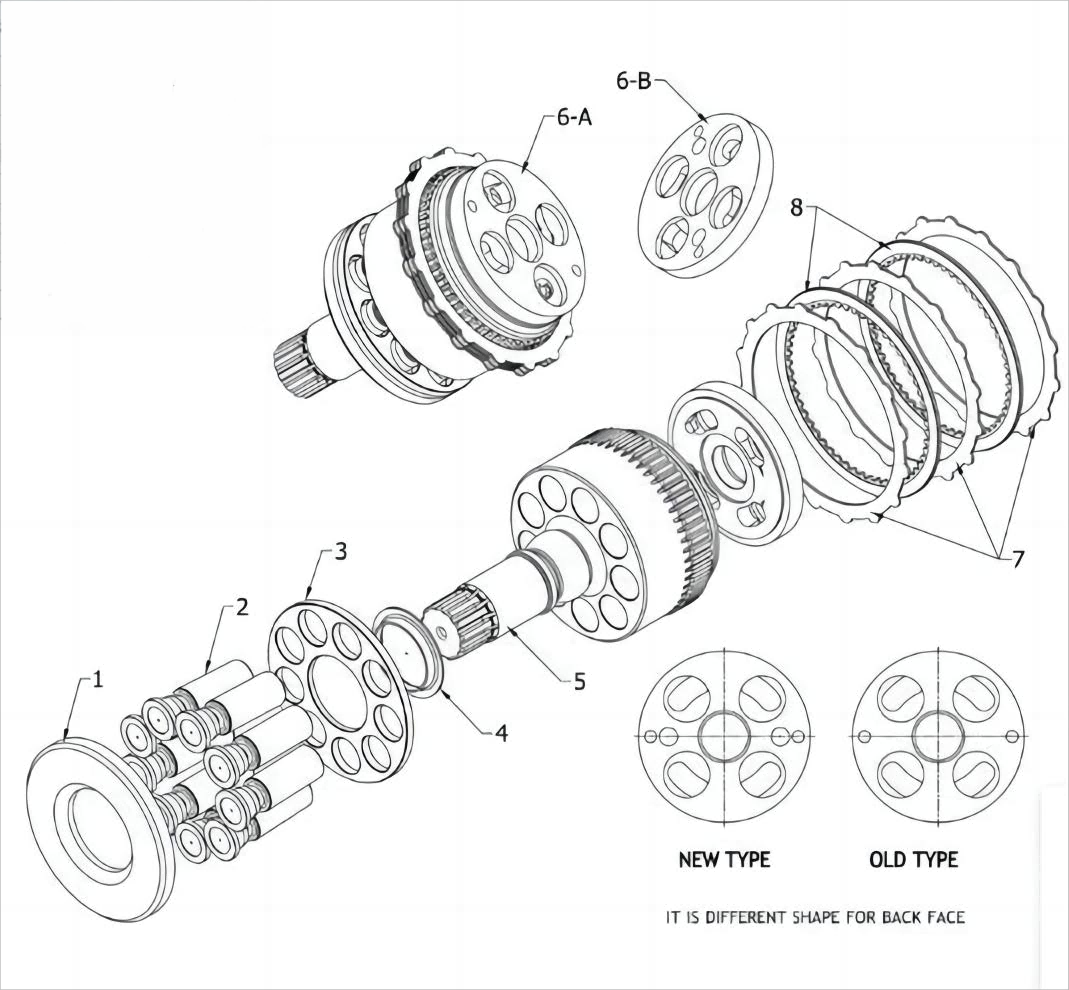

The components of a rotary motor include:

1. Swing assembly, consisting of cylinder, piston shoe, pressure plate and output shaft.

2. The brake assembly consists of a rotary brake control valve, a pressure plate, a friction plate, a brake piston and a brake spring.

3. The relief valve and oil supply valve are composed of a relief valve and a one-way valve.

4. Rotary damping valve.

How the Swing Motor Works

Working Principle: The hydraulic oil of the oil pump enters different oil passages and drives different plungers, sliding shoes, swash plates, etc., thereby achieving right rotation and left rotation.

Relief Valve in Swing Motor

The relief valve is installed on the top of the swing motor to limit the pressure of the rotary circuit to the set safe pressure range and slow down the impact when the swing motor starts or stops.

The relief valve is a two-stage design. When the relief valve is opened, there will be no excessive pressure, so when the swing motor stops, there will be little shock load.

As a key component of a hydraulic excavator, the swing motor's performance and quality are directly related to the excavator's production efficiency. The choice of accessories is crucial.

Copyright © 2026 Guangzhou Hansi Hydraulic Machinery Co.,Ltd. Support By BEE Cloud